US CHEMICAL STORAGE SOLUTIONS FOR THE

CHEMICAL INDUSTRY

The chemical industry operates under stringent regulations, with specialized requirements for the storage, handling, and processing of hazardous materials.

We specialize in designing cutting-edge facilities for the safe storage, mixing, dispensing, and waste isolation of industrial chemicals.

This wide category includes facilities that process petrochemicals, inorganics, paint, adhesives, coatings, degreasers, cleaners, and many other industrial chemicals.

We have experience with all of them, and our expertise ensures smart commercial chemical solutions with the features required for excellent performance, including:

- Gravity-fed roller racks

- Tote Storage

- Pallet Storage

- Gas Cylinder Storage

- Hot Boxes

- Cold Rooms

- Ventilation snorkels

- Eyewash stations and safety showers

We Can Make Your Process Easier

- Experience in the Industry – With over 30 years serving the largest chemical conglomerates in the world, we can handle the challenges you face every day to make your facilities safer and your material handling more efficient.

- State Permitting – If requested, we can handle the state-level regulations and permits to ensure your facility is fully compliant.

- Stamped Plans – Our in-house engineering team can provide stamped, certified plans that meet all necessary regulatory requirements.

- Transportation Coordination – We can schedule all transportation logistics utilizing experienced carriers, ensuring safe delivery to your site.

11,000

Chemical Manufacturing Facilities in the United States

96%

of All U.S. Goods Use Chemical Sector Products

1/4

of the U.S. GDP Relies on the Chemical Industry's Performance

CHEMICALS WE ROUTINELY ENGINEER FOR:

- Methanol

- Ethanol

- Acetone

- Xylene

- Toluene

- Ethyl Acetate

- Benzene

- Hexane

- Sulphuric Acid

- Sodium Hydroxide

- Nitrogen

- Proplyene

- Ethylene

- Dimethylfornamide

Specialized Chemical Industries

Inorganic & Organic Producers

Fertilizer Industries

Petrochemical & Energy Industry

Paint, Coatings, and Varnishes

Electroplating & Heat Treatment

Pesticide Industries

Cleaners & Degreasers

Plastics & Resins

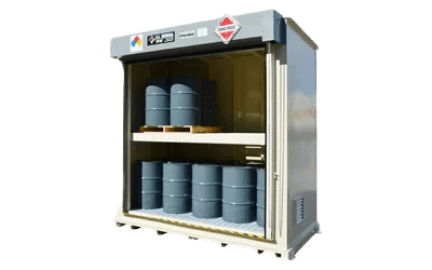

CASE STUDY

A TRANSFER SOLUTION

We engineered a transfer building designed to adhere to code compliance and prepare drums to safely move into 90-day storage utilizing a wide range of safety features and options.

Our Signature Products

FIRE-RATED BUILDINGS

Fire-rated hazmat storage buildings safely manage risks when storing the most dangerous flammable and hazardous chemicals. With 2-hour or 4-hour construction available, they can offer all the protection required.

NON-FIRE RATED BUILDINGS

All U.S. Chemical Storage non-fire rated hazmat buildings are perfect when the chemicals don’t require a fire rating, or you have space to distance the hazards from your people and property.

CHEMICAL LOCKERS

U.S. Chemical Storage engineers outdoor storage lockers with sumps to provide a quick, safe, and compliant solution to drum storage for 2 drums – to 16 drums.

EXPLOSIVE MAGAZINES

When dealing with explosives, magazines are essential for ATF regulations. We offer a wide variety of Type 2, Type 3, and Type 4 explosive magazine storage solutions to prevent disasters and avoid fines. Custom builds available.

PHARMA CLIENT:

“From design through installation, U.S. Chemical Storage has been great to work with… I feel like they were committed to making our project a success – unusual in a vendor!”

LEARNING RESOURCES

ARTICLES

How To Store Lithium Batteries

Lithium batteries are often used in today’s electronic environments.

Explosive Storage Magazines

Prevent accidents by storing your high and low explosives properly.

Pharma Hazmat Storage

This manufacturing process needed a compliant 90 day storage solution.

WE ARE HERE FOR YOU

NEED MORE INFORMATION?