US CHEMICAL STORAGE SOLUTIONS FOR THE

AUTOMOTIVE INDUSTRY

The automotive industry is incredibly fast-moving, and any storage requirements for hazmat and flammable must be high-performing and well-designed for product mobility.

At U.S. Chemical Storage, we design specialized buildings for chemical storage, mixing, dispensing, and waste isolation to enhance safety and profitability across all sectors of automotive production.

Our storage solutions are tailored to the industry’s specific demands, ensuring seamless product mobility and compliance with safety standards.

The automotive sector relies on various chemicals used in manufacturing, finishing, and assembly. With experience spanning numerous categories, we deliver intelligent, high-performing solutions that ensure excellent operational performance.

Our expertise covers the storage and handling of various chemicals essential to the automotive industry, such as:

- Flammables – Gasoline, solvents, starting fluids, and acetylene require specialized containment to prevent hazards and ensure safe operation.

- Lubricants – Oils, transmission fluids, hydraulic fluids, and grease are essential in vehicle production, and our storage systems ensure their safe and efficient use.

- Degreasers – Brake cleaners and solvents used in cleaning and maintenance require controlled environments to ensure safety and effectiveness.

- Paints & Coatings – Paints, lacquers, and paint removers need precise storage conditions to maintain their quality and safety during application.

- Adhesives – Epoxy resins used for bonding and adhesion require secure storage to preserve their integrity.

- Batteries – Both lithium-ion and lead-acid batteries are safely stored in our custom-engineered facilities.

We Can Make Your Process Easier

- State Permitting – If requested, we can handle the state-level regulations and permits to ensure your facility is fully compliant.

- Stamped Plans – Our in-house engineering team can provide stamped, certified plans that meet all necessary regulatory requirements.

- Transportation Coordination – We can schedule all transportation logistics utilizing experienced carriers, ensuring safe delivery to your site.

50%

of a car's volume is made of plastics

1.7 M

Number of Americans employed in the automotive industry

54%

of the weight of a car is steel

Chemicals We Routinely Engineer For

A few of the common chemicals we engineer buildings for in the automotive industry include:

- Acetylene

- Xylene

- Butyl alcohol

- Ethyl Acetate

- Toluene

- Benzene

- Ethylene Glycol

- Phosphoric Acid

- Epoxy Resins

- Fuels & oils

- Silicones

- Polypropylene

- Sodium azide

We Also Work With:

Textile Producers

Foam Fabricators

Resin & Plastic Formers

Paint Manufacturers

Coatings, and Varnishes

Electroplating & Heat Treatment

Marine & Ship Builders

Automotive Dealerships

EV Producers

Industry-Specific Expertise

- Modular Garage Construction – Buildings engineered in sections so nearly any size is possible with multi-truck shipments

- Battery Storage & Testing Areas – Built to the latest compliance and best practices for safe storage, charging, and testing of Li-On batteries.

- Mixing & Dispensing Rooms – Featuring eyewash stations and safety showers, ventilation snorkles, explosion-proof accessories, and temp control.

CASE STUDY

REPEAT CUSTOMER

This manufacturer and fabricator of customized emergency vehicles needed a hazmat building. What they got was a partner.

Our Signature Products

FIRE-RATED BUILDINGS

Fire-rated hazmat storage buildings safely manage risks when storing the most dangerous flammable and hazardous chemicals. With 2-hour or 4-hour construction available, they can offer all the protection required.

NON-FIRE RATED BUILDINGS

All U.S. Chemical Storage non-fire rated hazmat buildings are perfect when the chemicals don’t require a fire rating, or you have space to distance the hazards from your people and property.

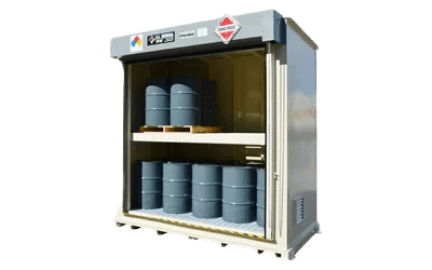

CHEMICAL LOCKERS

U.S. Chemical Storage engineers outdoor storage lockers with sumps to provide a quick, safe, and compliant solution to drum storage for 2 drums – to 16 drums.

EXPLOSIVE MAGAZINES

When dealing with explosives, magazines are essential for ATF regulations. We offer a wide variety of Type 2, Type 3, and Type 4 explosive magazine storage solutions to prevent disasters and avoid fines. Custom builds available.

PHARMA CLIENT:

“From design through installation, U.S. Chemical Storage has been great to work with… I feel like they were committed to making our project a success – unusual in a vendor!”

LEARNING RESOURCES

ARTICLES

How To Store Lithium Batteries

Lithium batteries are often used in today’s electronic environments.

Explosive Storage Magazines

Prevent accidents by storing your high and low explosives properly.

Pharma Hazmat Storage

This manufacturing process needed a compliant 90 day storage solution.