Racks and Shelves

U.S. Chemical Storage offers an assortment of fully customizable racks to help you store, organize, and access a large numbers of hazmat containers. Gravity sliding, multi-tier pallet racks, cylinder racks, drum racks and many other compliant rack accessories will increase the safety and production capacity of your operations.

Chemical storage building with racks

Get Organized with Storage Racks and Shelves

We also offer a variety of customizable shelving systems for organized storage of your chemical inventory.

Types of Racks and Shelves

Pallet Storage Rack

The pallet storage rack has multi-level storage for efficient storage, maximizing storage space to allow for ease of movement. It also helps you achieve compliance with government regulation while providing a safe environment for your team.

Pallet storage racks can accommodate between 2 and 48 pallets in a single building. Larger pallet capacity sizes and designs are available.

Rolling Tote and Pallet Storage Racks

Improve production capacity, safety, and forklift accessibility with our durable rolling tote and pallet rack system. Rollers built into the pallet and tote racks allow the pallet/tote in the back position to slide safely forward once the front pallet/tote has been removed. A stop plate is installed at the face of our racks to prevent safety issues or injury.

Sliding or push-back racking is available upon request.

Features & Benefits

- Simple loading and unloading system

- 100% structural steel

- 100% customizable

- No hydraulics required

- Extremely durable

Gas Cylinder Storage Racks

The durable gas cylinder rack allows you to vertically store and organize gas cylinder containers, increasing safety, accessibility, and production capacity when working with these potentially difficult containers. Customize your cylinder rack to house as many cylinders needed.

Heavy gauge steel construction will ensure your cylinders not only stay in the preferred, upright position, but also remain separated from other adjacent tanks. Your personnel will be able to take inventory with efficiency and can safely access your gas cylinder inventory.

Features & Benefits

- Safely store cylinders in an organized fashion

- Custom racks are available

- 1, 2 and 3 deep configurations

- No hydraulics required

- Extremely durable

Horizontal Drum Storage Racks

Our horizontal drum racks help maximize storage space while maintaining a safe storage environment within your facility. This drum rack is designed to support your chemical drums with our durable construction, securing hazardous materials and reducing chemical hazards.

Available in the following sizes:

- 2 drum, 1,600 lbs.

- 3 drum, 2,400 lbs.

- No hydraulics required

- Extremely durable

Built-In Rollers

Equipping your building with our gravity roller conveyor is an effective means of facilitating the chemical transportation process, allowing your personnel to safely access your chemical inventory.

The gravity roller conveyor organizes your chemical storage building, maximizing space and increasing productivity. Our rollers allow your team to move drums and other containers throughout the interior of your chemical storage building in an easy manner. Rollers are installed in sections that allow movement of these containers with floor grating installed to provide a safe path for personnel.

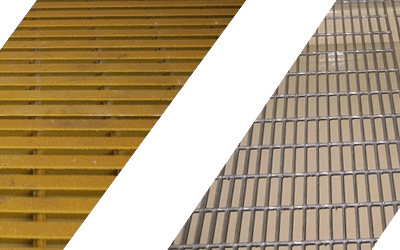

Shelving Options

Our chemical storage shelving systems offer increased organization, safety and security when storing valuable chemicals. Durable enough to withstand years of use, our line of shelves is constructed of extremely strong, high-quality steel. Options include galvanized spill containment shelving, stainless steel spill containment shelving, open mesh shelving and high capacity shelving. Most shelving options are adjustable in height.

Common Applications

- Hazardous Waste Storage

- Flammable and Combustible Storage

- Paint and solvent Storage

Downloadable Information & Fact Sheets

- Drawing: 2-Hour Bi-Direction Fire Rated Building (FL6115)

- Design Your Explosive Storage Magazine

- Warranty on Building & Accessories

- Buy or Build Chemical Storage Brochure

- Infographic: Choosing a Chemical Storage Building

- FireLoc 1-page Sheet

Compliance & Approvals

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Frequently Asked Questions

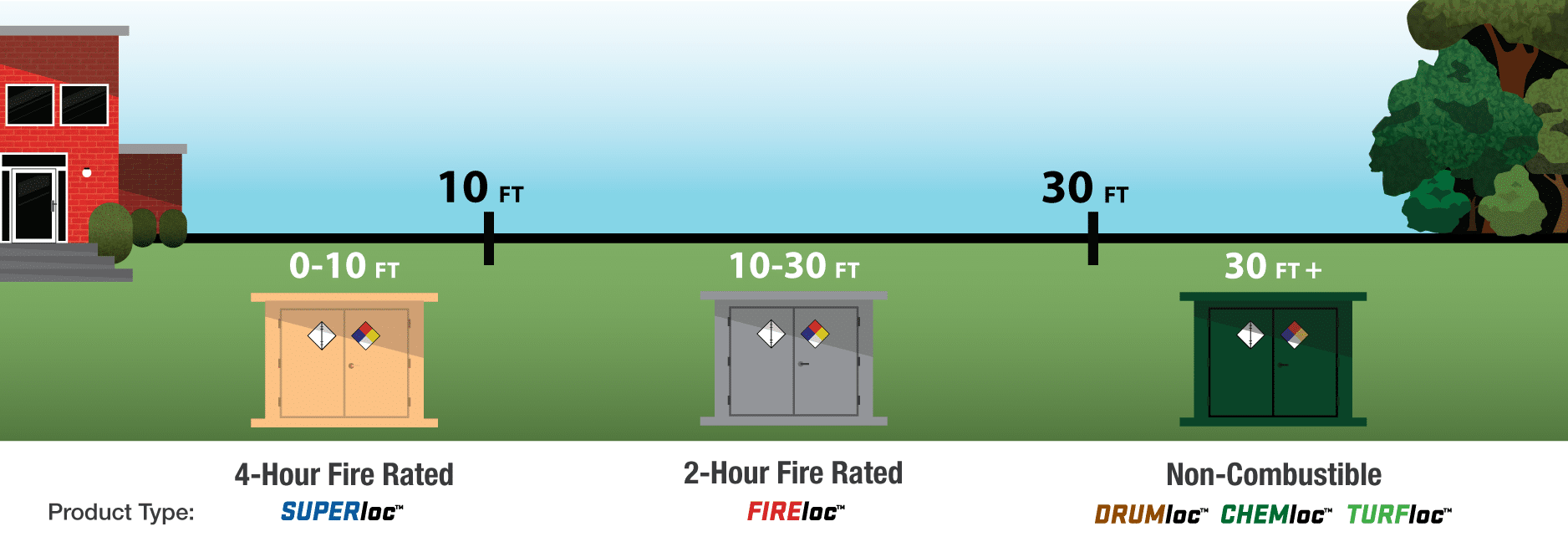

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

The definition of a “sump” is a pit or reservoir providing containment for spilled liquids. U.S. Chemical Storage offers leak-proof spill containment sumps in each standard model. All our sumps are tested for leaks for a 24-hour period prior to finishing. The sump is then covered by a steel or fiberglass floor grating and can even be equipped with a resistant plastic sump liner to protect against corrosive chemical accidental spills. The size of the sump is dictated by code based on the volume of liquid being stored within the building.

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials, and must take into consideration the most efficient way of moving these materials into and out of your chemical storage building.

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.

Request a Quote

RELATED PRODUCTS

Fire Suppression

Our fully customizable and compliant fire suppression systems and accessories help save lives and costly materials in the event of an emergency.

Flooring

Finding the right flooring for your chemical storage building is easy with the many U.S. Chemical Storage options.

Gas Sensors and Other Detection Systems

Improving employee safety means stopping problems before they even start. We offer a full line of gas sensors to do just that.

Partition Walls

Segregating chemicals with partition walls allows for the storage of multiple chemicals inside the same chemical storage building.

RELATED ARTICLES

How To Store Lithium Batteries

Lithium batteries are often used in today’s electronic environments.

Explosive Storage Magazines

Prevent accidents by storing your high and low explosives properly.

Pharma Hazmat Storage

This manufacturing process needed a compliant 90 day storage solution.