TurfLoc™ Agri-Chemical Storage Buildings

U.S. Chemical Storage provides safe, approved outdoor chemical storage buildings for agricultural and turf management chemicals. TurfLoc™ is the ideal non-fire rated chemical storage building for turf maintenance and agricultural professionals.

Designed for herbicide, fungicide, and pesticide storage, the flexible design of TurfLoc™ also makes it suitable for fertilizer and other agrichemicals.

Pesticide and Fertilizer Chemical Storage Buildings

Proper outdoor chemical storage buildings are constructed to reduce poison hazards or other accidents that affect the environment and our communities. This includes protecting crops, controlling weeds, insects and fungi, and altering the life cycle of harmful pests. Insurance carriers often require safe chemical storage practices to be in place before granting or renewing a policy. Failure to store chemicals according to regulatory standards could also result in fines. All U.S. Chemical Storage buildings meet EPA spill containment regulations and can be customized to meet NFPA requirements.*

We are your solution for safe chemical storage and compliance. Our TurfLoc™ buildings promote proper storage, handling, and disposal practices, enhance safety, and minimize contamination.

*Always consult your local authority with jurisdiction to ensure that all rules and regulations are followed, including proper setback requirements.

Features & Benefits

- Continuously welded, leak-tested sump

- Static ground connections

- Galvanized steel grate floor

- Forklift channels for easy relocation

- Available climate control

- 15-year structural warranty

- Chemical and UV resistant coating

- Natural draft ventilation

- 3-point lock door hardware

- Coal tar undercoating for corrosion protection

- Meets EPA, NFPA 30 and NFPA 1

- Fully customizable

Common Applications

- Agricultural Chemical Storage

- Pesticide Storage

- Fertilizer Storage

Downloadable Information & Fact Sheets

Compliance & Approvals

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Frequently Asked Questions

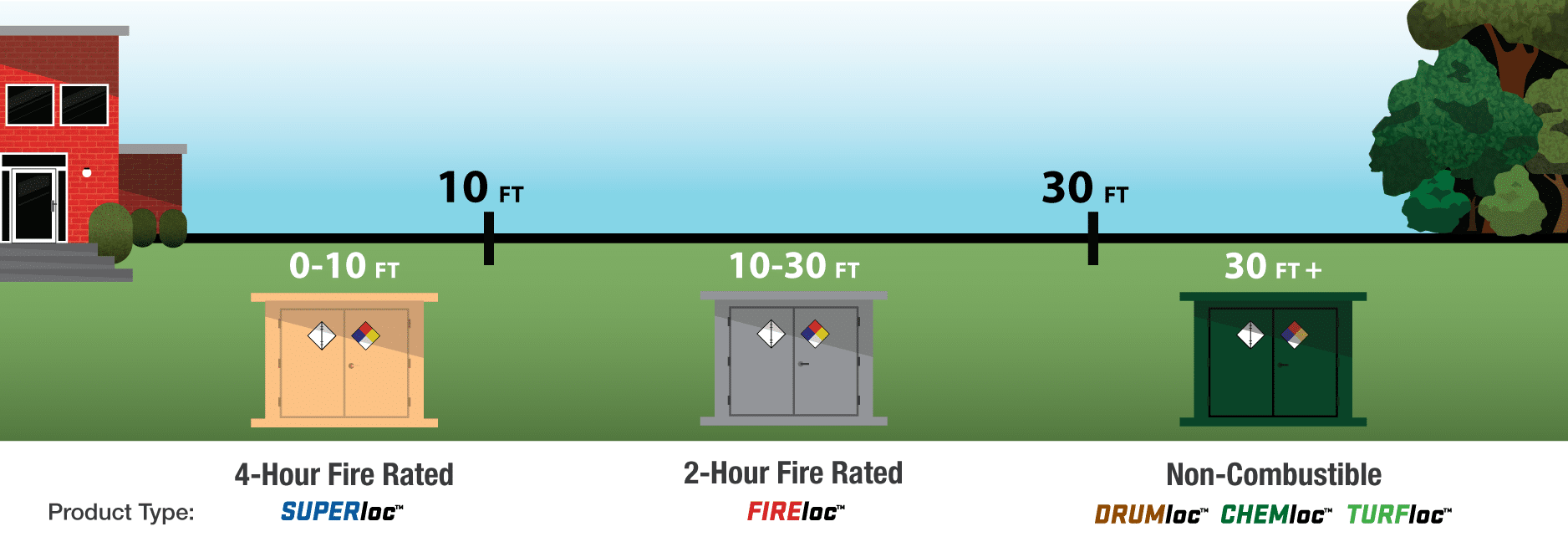

Start by speaking with one of our experienced Technical Sales Engineers to learn about the needs of your application. They will want to know what type of chemicals you are storing? How much of it will you be storing? What proximity to other buildings, people, egress paths, or environmental features will it need to be? Do you require special spill containment?

And from there they’ll ask any related questions that determine additional options; Material Handling – Climate Control – Ventilation – Occupancy – Lights – Sensors – Alarms – Door Styles – Eyewash Stations and other requirements are not uncommon. Answers to these questions will dictate the building’s fire rating construction as well as anything else you’ll need for proper code compliance.

The definition of a “sump” is a pit or reservoir providing containment for spilled liquids. U.S. Chemical Storage offers leak-proof spill containment sumps in each standard model. All our sumps are tested for leaks for a 24-hour period prior to finishing. The sump is then covered by a steel or fiberglass floor grating and can even be equipped with a resistant plastic sump liner to protect against corrosive chemical accidental spills. The size of the sump is dictated by code based on the volume of liquid being stored within the building.

Request a Quote

RELATED PRODUCTS

ChemLoc™ Chemical Storage Buildings

For unparalleled protection, use non fire-rated hazardous chemical storage buildings for storing flammable or combustible chemicals at least 30 feet from other buildings. These chemical storage units have countless applications and accessories that can be custom engineered to fit your specific needs.

DrumLoc™ Chemical Drum Storage Buildings

DrumLoc™ is a safe and secure non fire-rated storage building and provides ideal protection for large quantities of hazardous chemicals. Each chemical drum storage building can be outfitted to hold from two to 56 drums and will accept a variety of accessories to make operations flow safely and smoothly.

RELATED ARTICLES

Safe Fertilizer Storage Helps Keep the Fairways Green

Fertilizer chemical storage buildings and pesticide storage lockers ensures you maintain compliance with OSHA and keeps agriculture chemicals stored safely.

How To Choose a Proper Chemical Storage Building

How To Choose a proper chemical storage building that keeps employees safe and is compliant with OSHA, the IBC, and the NFPA.

Chemical Storage Buildings: What Style Fits Your Needs?

U.S. Chemical Storage provides two common styles of chemical storage buildings – occupancy walk-in style and non-occupancy rack style. Which one is right for you?

YOUR PARTNER IN THE PROCESS. EXPERIENCE YOU CAN TRUST.

We deliver the precise building solution with the speed, security, and high quality that you demand.