Personal Safety

U.S. Chemical Storage buildings are designed to facilitate the chemical storage process, but protecting personnel who handle hazardous materials is even more important.

* 45GP with optional treadle (left)

* H5G45G with optional treadle (right)

Types of Personal Safety Accessories

Emergency Safety Showers and Eyewash Equipment

Chemical spills, drips, and splashes are sometimes unavoidable. Be prepared with an emergency safety shower and eyewash equipment. View Product >Other Safety

Accessories

We offer numerous accessories designed to protect personnel from hazardous risks and injury.

View Product > Emergency Safety Showers In Your Building

U.S. Chemical Storage buildings are designed to facilitate the chemical storage process, but protecting personnel who handle hazardous materials is even more important. Provide your workers with direct access to safety solutions with our many personal safety accessories, including emergency safety showers and eyewashes, signage, material handling equipment, and more.

We can offer a variety of emergency eye wash and shower stations that comply with ANSI standards and OSHA requirements. The ANSI/ISEA Z358.1 standard provides guidelines for the location and performance of emergency eye wash and shower station. It states the equipment must be on the same level and within 10 seconds of an identified chemical hazard – approximately 55 feet. The path to reach it must be free of any obstacles or equipment.

Safety Shower flow rates must meet the need for enough flow of water to flush the affected area completely. They require a minimum supply of 20 gallons per minute at a pressure of 30 lbs. per square inch for at least 15 minutes. If the water supply is too hot or too cold, it may cause further harm to the injured person. That’s why ANSI specifies the water temperature must be in the tepid range of 60° to 100° F (16° to 38° C).

We offer different models for different applications. Workplace safety is fundamentally about the people you strive to protect and the environments in which they live and work. In an emergency, safety showers and eye washes can be the difference between life and death.

Annual inspections certify that the emergency safety shower remains compliant with the ANSI requirements. Validate water temperature, flow rate, location, operation, etc. on an annual basis. This makes sure the equipment is performing how it should and providing the right level of emergency relief.

Justrite: Meet OSHA Emergency Shower Requirements

Features & Benefits

- Safe storage of flammables in locations close to existing structures

- Compliant with EPA, OSHA and NFPA requirements

- 100% customizable to meet your specific needs

- 15-year structural warranty

- Modular construction available for larger sizes

Downloadable Information & Fact Sheets

Compliance & Approvals

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Frequently Asked Questions

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

Chemical storage buildings manufactured by U.S. Chemical Storage are designed to get your operation compliant. Contact one of our technical sales engineers to learn how we can find the best solution for your compliance needs. You will also want to learn more about specific chemical storage requirements in your specific area by contacting your local “Authority Having Jurisdiction” (AHJ) who could be a local fire marshal, a municipal code official, or a city environmental department.

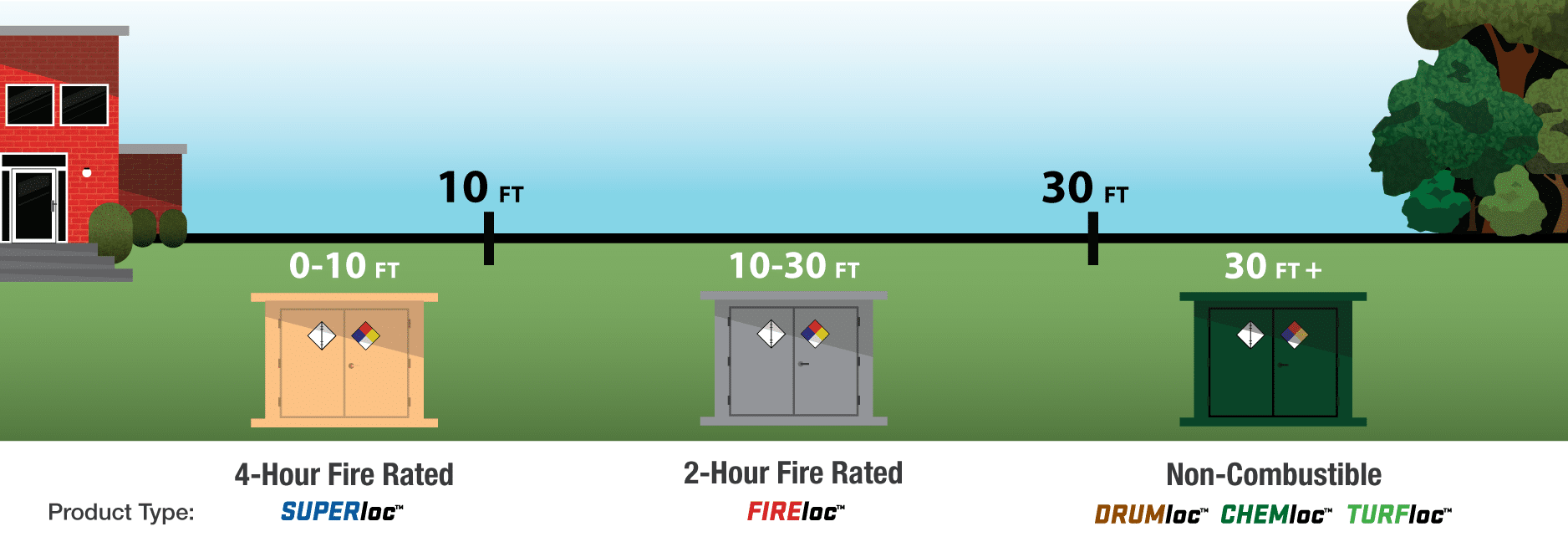

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.

Request a Quote

YOUR PARTNER IN THE PROCESS. EXPERIENCE YOU CAN TRUST.

We deliver the precise building solution with the speed, security, and high quality that you demand.