SuperLoc™ Flammable Storage Buildings

The U.S. Chemical Storage SuperLoc™ 4-hour fire rated hazardous storage buildings allow for flammable storage located within 10 feet from and even inside your facility.* Such proximity can prove advantageous as it grants faster production, distribution and storage of your valuable flammables and combustibles.

Constructed from high quality steel, all SuperLoc™ buildings include built-in, leak-tested secondary containment sumps for spill containment, coal tar undercoating, and chemical and weather-resistant coatings inside and out.

Maintaining compliant chemical storage is important for many reasons, including avoiding insurance costs, fines, fires and hazardous spills. SuperLoc™ flammable storage buildings are the top the of U.S. Chemical Storage line. Each building can provide years of use, as supported by our 15-year structural warranty. All buildings can be highly engineered with a variety of optional accessories to customize your storage solutions. Explosion control systems featuring C1D1 and C1D2 options and FM-approved explosion relief construction can be included.

4-Hour Flammable Storage

Use SuperLoc™ hazardous storage buildings to achieve compliance and make your manufacturing and chemical storage management more efficient. Completely customizable, SuperLoc chemical storage buildings are manufactured in bi-directional 4-hour fire rated weather-resistant construction. All buildings feature mineral wool insulation installed in the wall cavity.

Multiple layers of UL Classified fire-resistant gypsum wallboard encased between heavy gauge steel for maximum fire protection. Optimize your chemical storage capabilities with a variety of optional explosion proof and non-explosion proof rated, fire rated safety accessories. U.S. Chemical Storage offers options for climate control, fire suppression, mechanical ventilation and more.*

Many configurations and types of storage buildings are available, including modular construction for larger sizes. All 4-hour fire-rated flammable storage buildings can meet EPA and NFPA regulations, have a standard wind load of 120 m.p.h, and can be manufactured to FM or Warnock Hersey standards.

*Always consult your local authority having jurisdiction (AHJ) to ensure that all rules and regulations are followed for your location, including distances from people, other property, and proper setback requirements.

Cutting Edge Wall Design

SuperLoc™ flammable liquid storage buildings boast a tested and approved bi-directional wall design and come standard with R12 insulation in the cavity. Each building is rated to a wind load of at least 120 m.p.h. per ASCE-7-10.

Features & Benefits

- Weather-resistant steel construction

- Chemical & UV resistant coating

- Manufactured to meet EPA, NFPA 30 and NFPA 1

- 4-hour fire-rated

- Continuously welded, leak-tested sump

- Walk-in or rack and roll-up door style available

- 15-year structural warranty

Common Applications

- Paint Mixing and Storage

- Flammable and Combustible Storage

- Organic Peroxide Storage

Downloadable Information & Fact Sheets

- Buy or Build Chemical Storage Brochure

- Infographic: Choosing a Chemical Storage Building

Compliance & Approvals

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Frequently Asked Questions

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

The definition of a “sump” is a pit or reservoir providing containment for spilled liquids. U.S. Chemical Storage offers leak-proof spill containment sumps in each standard model. All our sumps are tested for leaks for a 24-hour period prior to finishing. The sump is then covered by a steel or fiberglass floor grating and can even be equipped with a resistant plastic sump liner to protect against corrosive chemical accidental spills. The size of the sump is dictated by code based on the volume of liquid being stored within the building.

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials, and must take into consideration the most efficient way of moving these materials into and out of your chemical storage building.

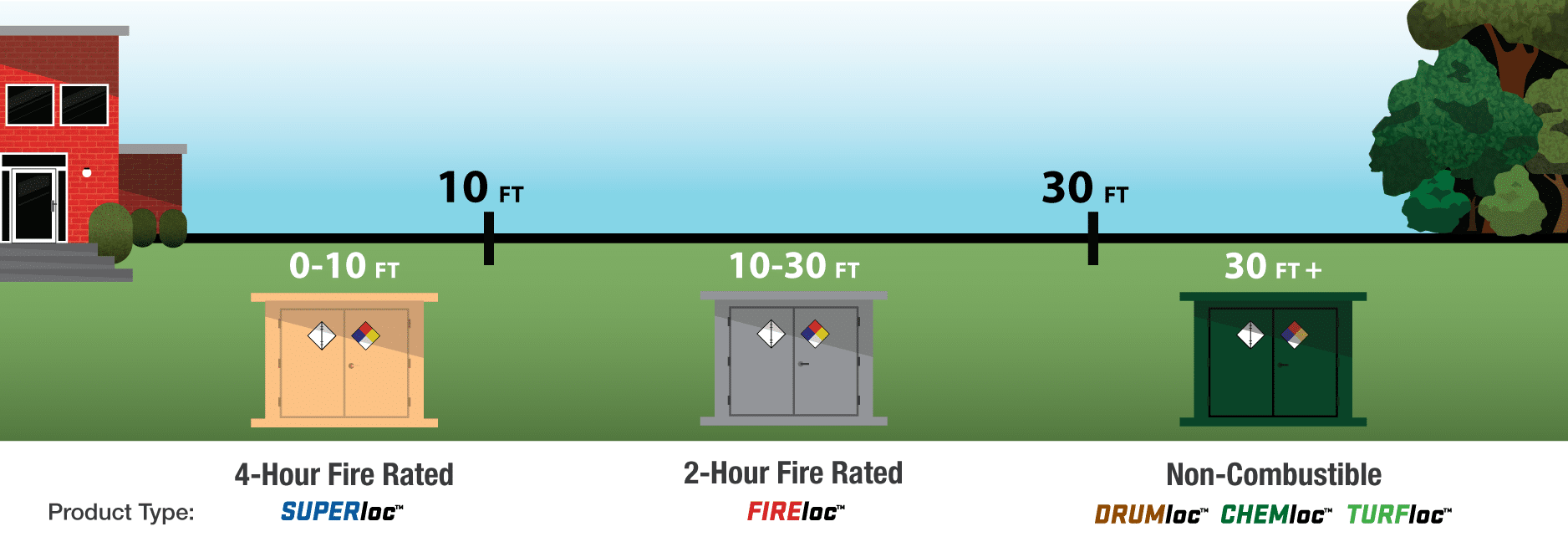

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.

Request a Quote

RELATED PRODUCTS

DynaLoc™ Type 3 Daybox

U.S. Chemical Storage manufactures a durable Type 3 explosive magazine, also known as a “daybox,” for temporary, supervised storage. Our daybox for explosives helps your team safely transport small amounts of explosives from your standard storage.

Non-Fire Rated Buildings

All U.S. Chemical Storage non-fire rated hazardous storage buildings are professionally manufactured with one goal in mind: durability.

Chemical Lockers

U.S. Chemical Storage manufactures highly portable, pre-engineered chemical storage lockers to provide a quick, safe, and compliant solution to chemical storage when full customization is not necessary.

Explosive Storage Magazine

When dealing with explosives, safety is essential to a successful outcome. We offer several types of explosive magazine storage to prevent disasters and avoid fines.

YOUR PARTNER IN THE PROCESS. EXPERIENCE YOU CAN TRUST.

We deliver the precise building solution with the speed, security, and high quality that you demand.